The following procedure will be used when the CEM daily autocalibration is not working due to failure or human intervention. The data system must be in "Maintenance" mode during this process.

This procedure is only to document that the readings from the CEM system are valid and is a short term substitution for the automatic daily calibration.

After the reading have settled to stable values record both the Oxygen and the CO concentrations from the Servomex display. The O2 will be span value and CO will be "zero" for Carbon Monoxide both ranges. Oxygen should be between 20.5 and 21.5. If not a calibration of the Servomax is necessary.

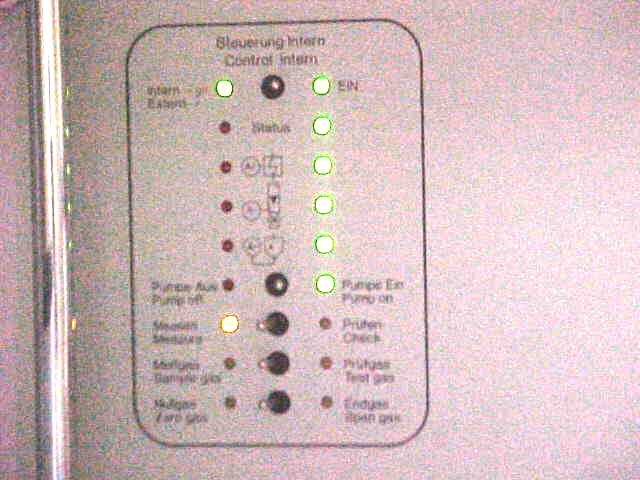

Flip the bottom toggle switch on the SCS to "Span Gas". Make sure the rotary swith to the right of the toggle switches is pointing to "1". The system must achieve 95% of known within 2 minutes of introduction of the gas. After the readings have reached a stable level record both O2 and CO readings as O2 "zero" and CO span 1. The O2 zero should be between -0.5 and 0.5. The CO must be between 133 and 147 when using 140 ppm gas.

Turn the rotary switch to "2" and wait to record the CO span 2 reading. This reading must be between 1900 and 2100 ppm when using 2000 ppm CO as span gas 2.

After calibrations are completed return all toggle switches to their original position, Return the Span 1 or 2 switch to #1 After readings have returned to normal levels go to Evaps Control and return the "virtual" maintenance switch to OFF. Note the time on the window.

Log in the fact of the manual calibration in the book which is kept inside the Servomex enclosure. Note the time spent in maintenance mode and record this time to the nearest ¼ hour in the log book.